Have you ever noted how a contact lens left to dry, wrinkles up and loses its shape, but if put back in its contact lens solution it returns to its original shape? The function and properties of many natural and man-made materials depend on their ability to take up and release water. Contact lenses are one example, but also thickeners and emulsifiers in food and cosmetics, and filtration devices, all depend on the ability of the material to hydrate and dehydrate. In research and product development, it is therefore highly relevant to study swelling processes of these materials. This can be done with QCM-D, a surface-sensitive technology which can be used to characterize and optimize water uptake and release processes in thin films.

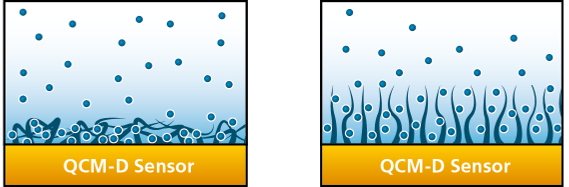

The amount of water in a thin film can be > 95% depending on the molecules and molecular conformation at the surface. As an example, think of elongated molecules adsorbing flat on the surface, Figure 1. A layer with this molecular arrangement will only a small amount of water, while more water will be able to couple to the molecules if they instead adsorb in an upright fashion. The hydration and dehydration of molecular layers, and the transition between these two states, can be characterized with QCM-D, where the water uptake and swelling are sensed as an increase in mass at the surface.

Figure 1. Molecules adsorbed flat onto a surface (left) couples less solvent than when adsorbed in an upright fashion (right).

As an example, let’s have a look at moisture uptake in a starch film. Starch is an important ingredient in for example the paper industry and in the design of edible films. In both areas, the effect of the ambient humidity on the material strength and quality is a central question. In the context of paper, the solubility should be low so that the paper quality is stable in range of ambient humidity. For edible materials on the other hand, the material should dissolve, and the solubility needs to be high above a specific ambient humidity.

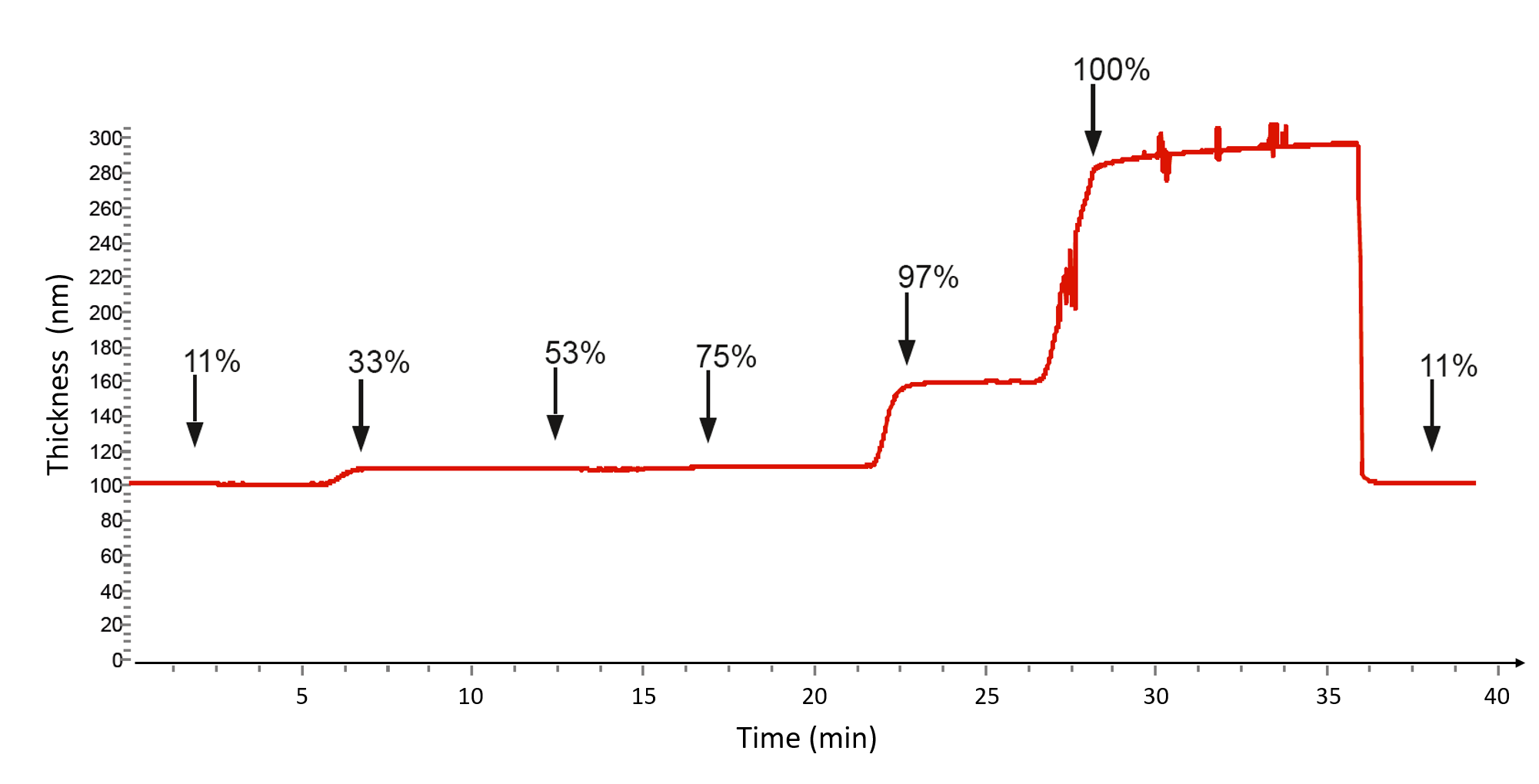

In this example1, we expose a thin film of native potato starch to air of different humidity while measuring the change in film thickness, Figure 2.

This measurement shows how the humidity induces swelling of the film and affects the thickness. The results give insight into how the material behaves under different humidity conditions.

Figure 2. Analyzing vapor uptake and thin film swelling.

In addition to the pulp and paper industry, measurements of vapor uptake and thin film swelling are relevant in many other areas where hygroscopic materials are used. Examples are in drug encapsulation for storage and delivery and in water sensitive applications, such as in the design of materials in humidity-resistant devices, where the properties of the material must be unaffected by changes in ambient humidity. Swelling phenomena also occur in many other contexts, for example in cleaning processes where surfactants induce soil swelling, and in the design of smart materials, which are responsive to pH, temperature or ionic strength.

Download the application note to read the full study

1. Measurements by Biolin Scientific in collaboration with the Department of Polymeric Materials, Chalmers University of Technology, Sweden.

Read the guidelines on how to decide which QCM instrument will be the most suitable for your needs

Read about how protein adsorption at various surface and solution conditions quickly can be measured

Read about what single-harmonic and multi-harmonic QCM-D means and what the difference is between these instruments.

Read about how QSense QCM-D analysis is used as a powerful tool to investigate protein-lipid nanoparticles binding affinity

Learn about the difference between the theoretical QCM sensitivity and the sensitivity which is relevant in a measurement situation.

Read about the piezoelectric effect and how piezoelectricity arises

Learn more about QSense 4th generation QCM-D platform which provides a sharper tool in the scientist toolbox and simplifies data interpretation.

Learn about how biointerfaces and biomolecular interactions can be studied using QSense® QCM-D and what information these measurements offer.

Read about Prof. Jackman's experience using QCM-D to study surfactant-interaction with model membranes